Boatbuilding

As part of my Quantitative Engineering Analysis class, in a team of two, we built a boat out of shrink wrap and HDF, that floated flat, carried 750g of payload and had an angle of vanishing stability(AVS) between 120 to 140 degrees, within a week.

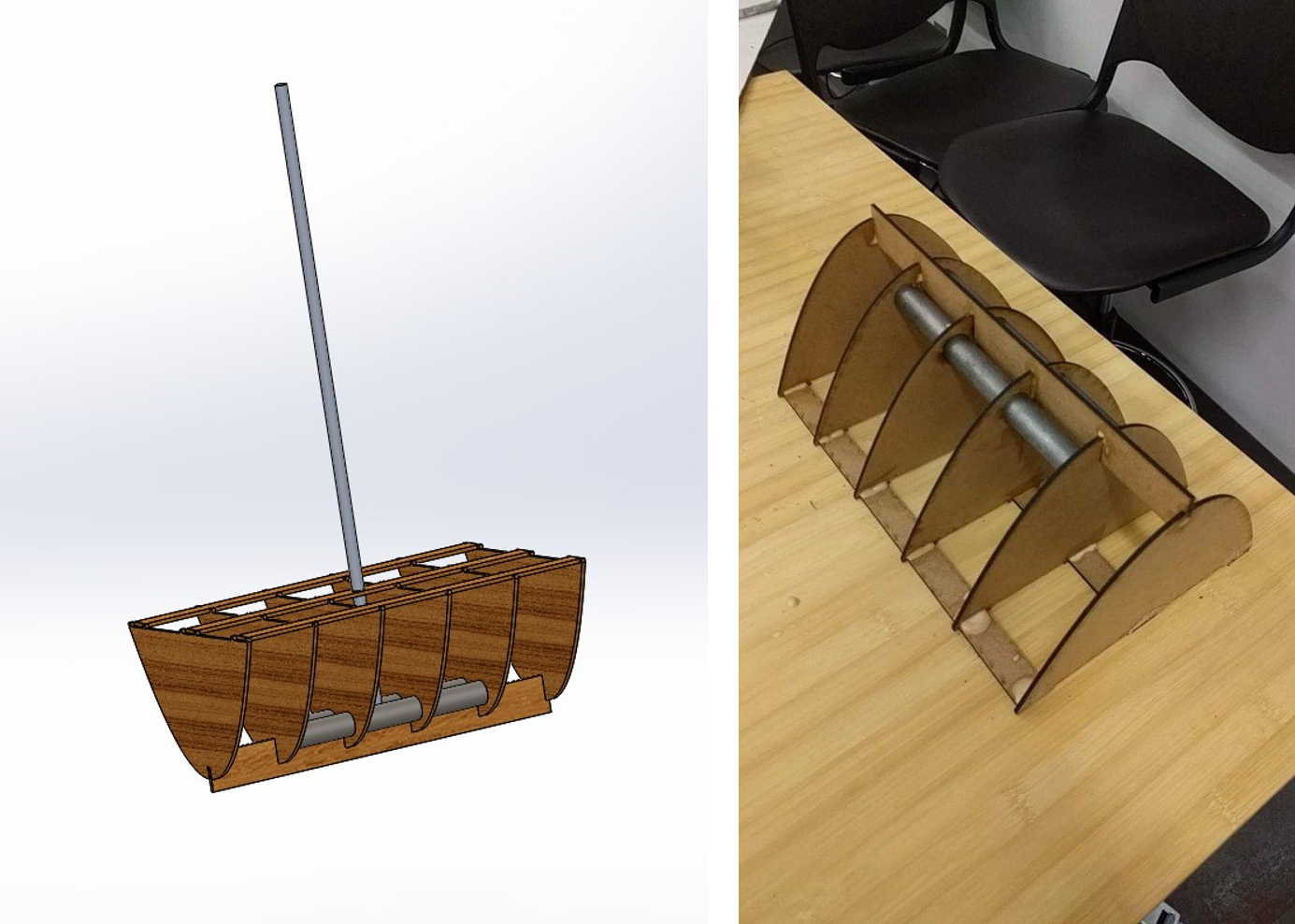

We used Mathematica to do a 3D model of the boat and optimize for the right dimensions to float flat and have the right AVS angle, designed the parts in Solidworks laser-cut the parts and did the assembly, within a week.

The major challenge that we foresaw before starting the project was the angle of vanishing stability, which was defined by the righting moment that buoyancy exerts about the center of mass. Therefore the first thing we modeled, was the locations of the center of mass and center of buoyancy. As seen in the image above, as the boat tips, the center of buoyancy with respect to the center of mass. Since we could calculate how much the force of buoyancy was, all we had to do was to simulate the moment arm with Mathematica and calculate the moment.

Using this information, we plotted the moment arm with respect to the amount of roll of the boat, changed the placement and mass of the payload, until the AVS was in the acceptable range. As seen in the plot below, the righting moment becomes zero at around 138 degrees, which is our AVS.

I used Solidworks to CAD our boat, with respect to the parameters that we determined and checked to see if the center of mass is where we calculated it was. After we laser cut the rib, we put the pieces together and wrapped it in shrink wrap. Once the boat was physically built, it passed all the tests on the demonstration day, and could float flat and display its AVS of 138 degrees.

- Design: HTML5 UP